As global demand for cement, construction materials, agricultural products, and industrial granular substances continues to grow, the packaging industry faces increasing pressure to deliver high-strength, consistent, and cost-efficient paper valve bags at scale. Manufacturers are no longer satisfied with conventional equipment that struggles with speed, stability, or automation. Instead, the focus has shifted toward high-speed tube forming solutions that can seamlessly integrate into modern paper valve bag manufacturing lines.

High-speed tube forming machines play a critical role in shaping paper tubes that form the foundation of valve bags. When combined with intelligent control systems and downstream valve bag making equipment, these solutions enable manufacturers to achieve higher productivity, reduced waste, and superior bag quality. Companies like DESHENG, with extensive experience in valve bag production technology, are helping packaging producers transition from traditional setups to fully optimized, high-speed production lines.

This article explores how high-speed tube forming solutions are transforming paper valve bag manufacturing, the key technologies involved, and why intelligent, integrated systems are becoming the industry standard.

Understanding Paper Valve Bag Manufacturing

Paper valve bags are widely used for packaging cement, activated carbon, chemical powders, and agricultural granular products. Unlike open-mouth bags, valve bags require precise tube forming to ensure:

- Accurate bag dimensions

- Strong longitudinal and transverse seams

- Smooth valve insertion and reliable self-closing behavior

The manufacturing process typically includes:

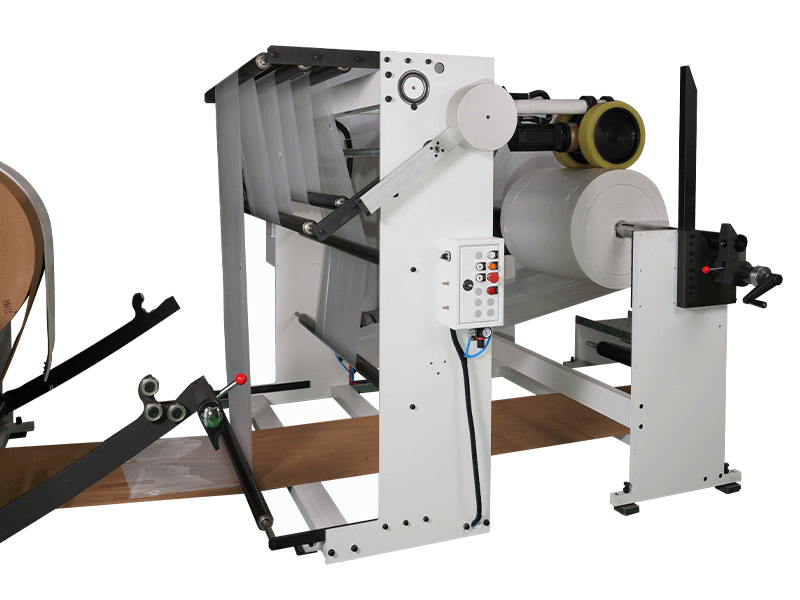

- Paper feeding and tube forming

- Tube cutting and shaping

- Valve insertion and forming

- Bottom forming and sealing

- Quality inspection and stacking

Among these steps, tube forming is the structural core. Any inconsistency at this stage directly affects downstream processes and final bag performance.

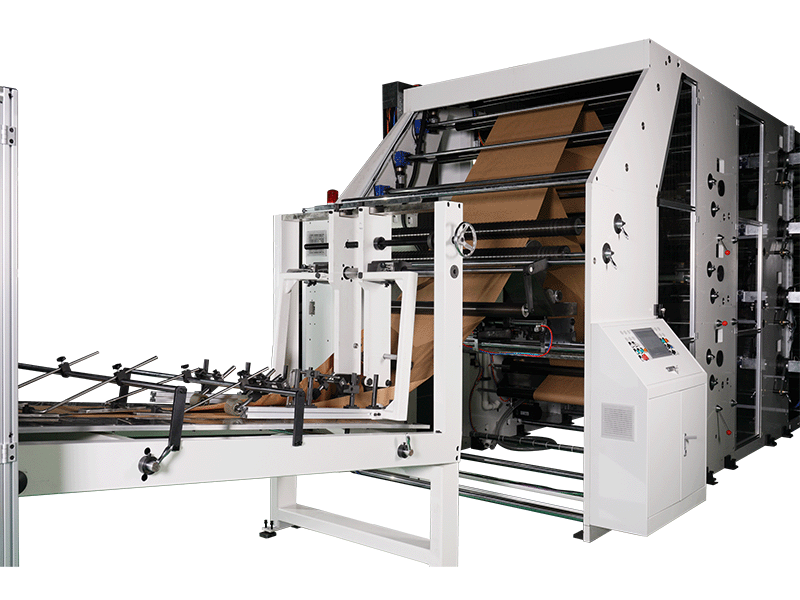

What Is High-Speed Tube Forming?

High-speed tube forming refers to the process of shaping paper sheets into continuous tubes at significantly higher production speeds, while maintaining dimensional accuracy and structural strength. Unlike conventional tube formers, high-speed solutions rely on:

- Precision forming components

- Stable tension control systems

- Servo-driven motion and intelligent synchronization

- Automated fault detection and adjustment

In paper valve bag manufacturing, this technology ensures that the formed tube is perfectly aligned for valve insertion and bottom forming, even at high output rates.

Key Advantages of High-Speed Tube Forming Solutions

1. Increased Production Efficiency

One of the most immediate benefits of high-speed tube forming is output capacity. Modern systems are designed to operate continuously with minimal downtime, making them ideal for large-scale valve bag production lines.

Manufacturers can meet growing demand without expanding factory space or increasing labor costs, which directly improves return on investment.

2. Consistent Tube Quality

High-speed does not mean sacrificing quality. On the contrary, intelligent tube forming systems use precise control algorithms to ensure:

- Uniform tube diameter

- Accurate overlap and seam alignment

- Stable paper tension during forming

This consistency is essential for producing paper valve bags that can withstand heavy granular materials such as cement or activated carbon.

3. Reduced Material Waste

Material waste is a major cost factor in paper packaging. Poor tube forming leads to misalignment, rejected bags, and excessive paper consumption.

High-speed tube forming solutions from experienced manufacturers like DESHENG are engineered to optimize paper usage while maintaining structural integrity, helping producers reduce scrap rates and improve overall material efficiency.

4. Seamless Integration with Valve Bag Machines

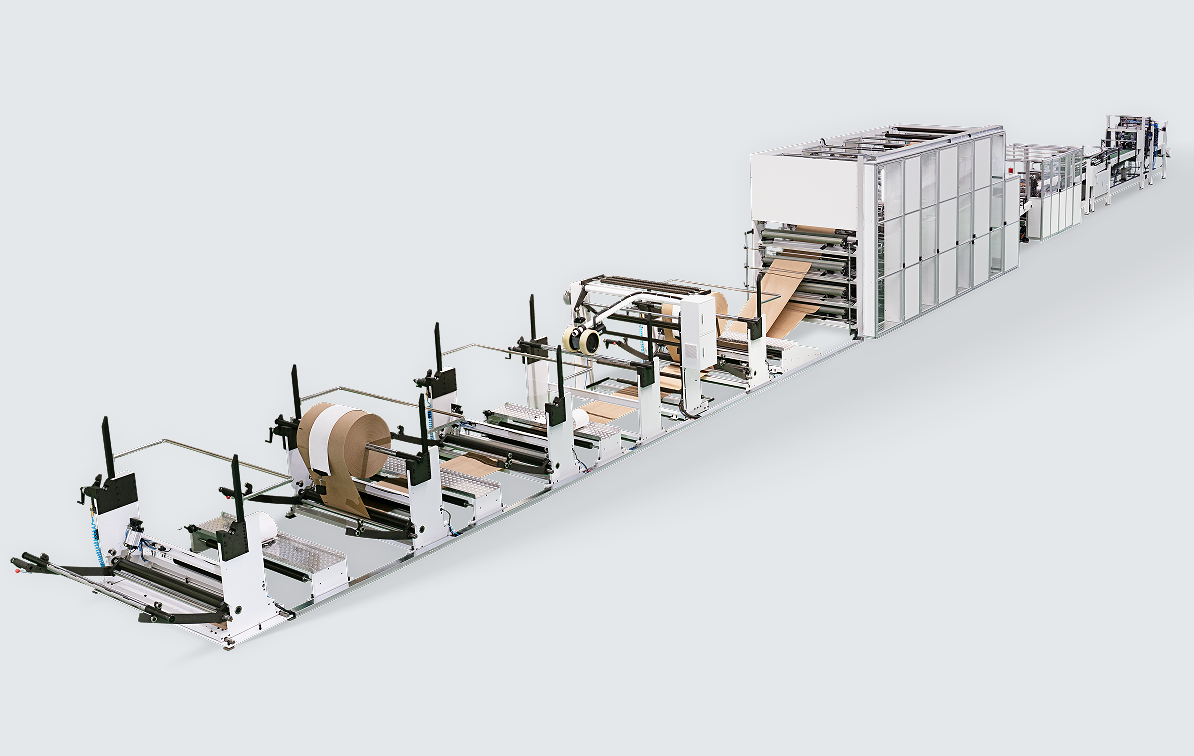

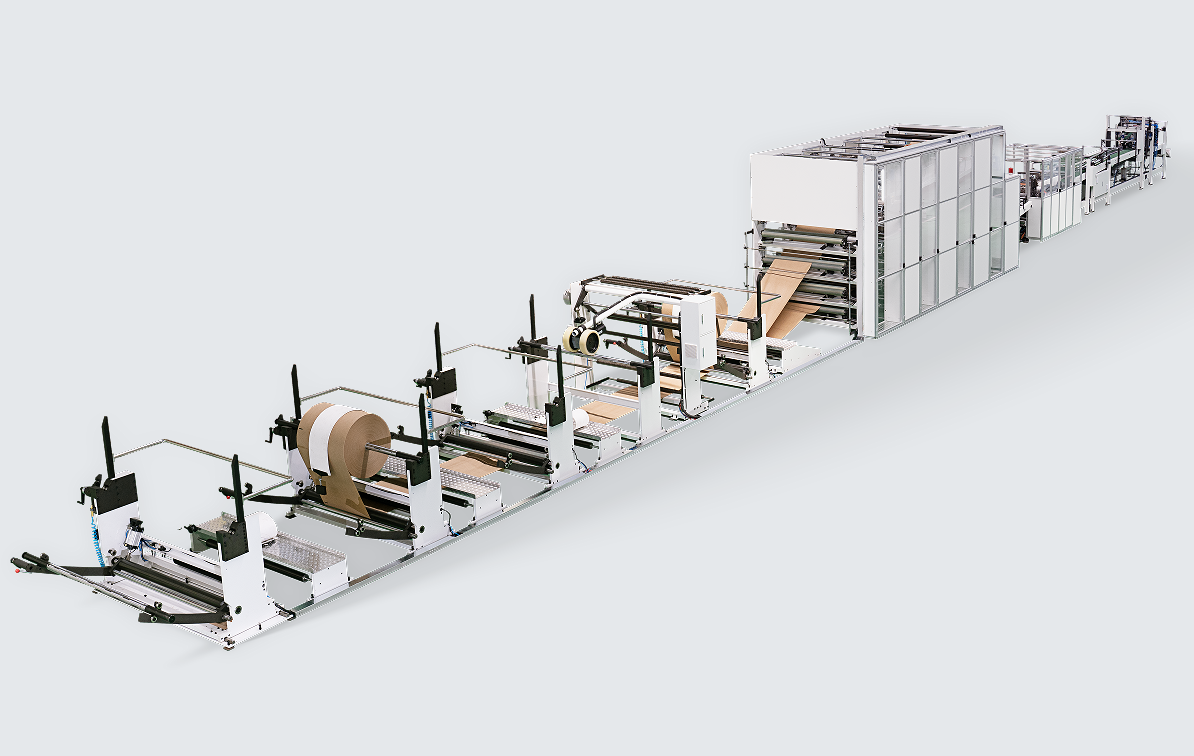

A tube forming machine does not operate in isolation. Its real value lies in how well it integrates with:

- Valve bag making machines

- Valve bag base machines

- Downstream stacking and palletizing systems

DESHENG's high-speed tube forming solutions are designed as part of a complete paper valve bag production line, ensuring smooth data communication and mechanical synchronization across all units.

The Role of Intelligent Control Systems

Automation and Precision

Modern high-speed tube forming solutions rely heavily on intelligent control systems. These systems monitor parameters such as speed, tension, and alignment in real time, automatically adjusting settings to maintain optimal performance.

This level of automation reduces reliance on operator experience and minimizes human error, making production more predictable and scalable.

Real-Time Monitoring and Diagnostics

Advanced systems offer real-time monitoring interfaces that allow operators to:

- Track production speed and output

- Detect deviations in tube quality

- Identify potential issues before they cause downtime

By integrating these capabilities, DESHENG helps manufacturers maintain stable production even under demanding operating conditions.

Applications in Paper Valve Bag Manufacturing

High-speed tube forming solutions are particularly valuable in industries where strength and reliability are critical.

Cement Packaging

Cement valve bags must handle heavy loads and abrasive materials. Precise tube forming ensures uniform wall thickness and strong seams, reducing the risk of bag failure during filling and transportation.

Activated Carbon and Chemical Products

Fine granular materials require bags with consistent internal volume and precise valve positioning. High-speed tube forming supports these requirements by delivering stable tube geometry at high throughput.

Agricultural Products

From fertilizers to grains, agricultural packaging demands both durability and efficiency. Intelligent tube forming solutions enable manufacturers to respond quickly to seasonal demand peaks without compromising quality.

Why Manufacturers Choose DESHENG

As a specialized supplier of paper valve bag production equipment, DESHENG offers more than individual machines. The company provides integrated high-speed tube forming solutions that are engineered to work seamlessly with valve bag making machines and valve bag base machines.

Key strengths of DESHENG include:

- Proven experience in paper valve bag manufacturing technology

- Focus on high-speed, intelligent automation

- Equipment designed for heavy-duty industrial applications

- Flexible configurations to meet different production requirements

Rather than promoting a one-size-fits-all approach, DESHENG works closely with manufacturers to tailor solutions that match specific materials, output targets, and factory layouts.

Building a Complete High-Speed Valve Bag Production Line

A successful paper valve bag manufacturing setup depends on how well each component works together. High-speed tube forming serves as the backbone of the line, supporting:

- Stable upstream paper handling

- Accurate valve insertion

- Reliable bottom forming and sealing

When implemented as part of an integrated system, manufacturers gain better control over quality, cost, and delivery timelines.

DESHENG's approach emphasizes system-level optimization, ensuring that tube forming speed aligns perfectly with downstream processes.

Future Trends in Tube Forming Technology

The future of paper valve bag manufacturing lies in:

- Greater automation and digitalization

- Data-driven process optimization

- Energy-efficient machine designs

- Smarter integration across the production line

High-speed tube forming solutions will continue to evolve, becoming faster, more precise, and more intelligent. Manufacturers that invest early in advanced systems are better positioned to remain competitive in global packaging markets.

Conclusion

High-speed tube forming solutions are no longer optional for manufacturers aiming to stay competitive in paper valve bag manufacturing. They are a strategic investment that enables higher output, consistent quality, and reduced operational costs.

By combining intelligent control systems with robust mechanical design, companies like DESHENG are helping producers build efficient, future-ready valve bag production lines. For manufacturers packaging cement, activated carbon, agricultural products, or other granular materials, high-speed tube forming is the foundation of reliable and scalable production.