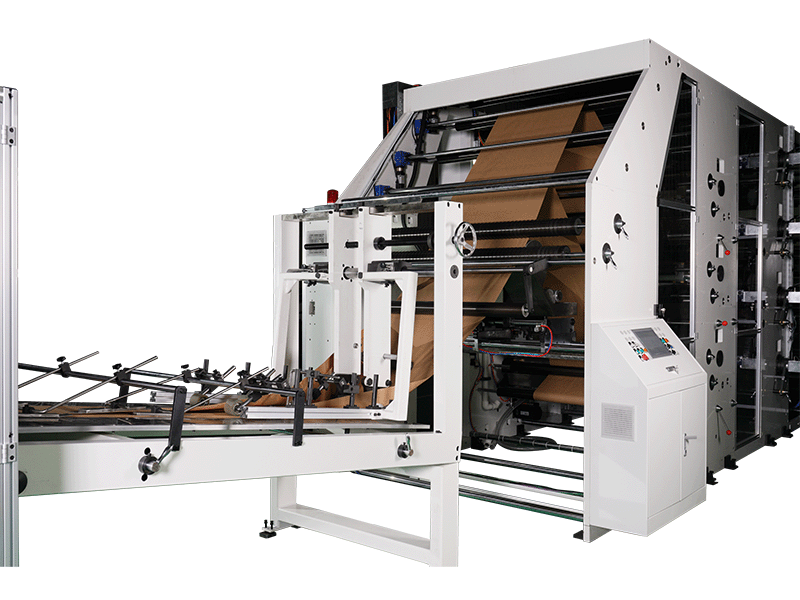

This cement bag production line is composed of our company's valve bag making machine and valve bag base machine, suitable for producing paper valve bags for storing granular substances such as cement, activated carbon, and agricultural products.

| TBGS2025 High-Speed Intelligent Tube Making Machine Main Parameters | |

| Model | TBGS2025 |

| Normal Production Speed | 1.280-350 pcs/min (for mortar building material bags) 2.200-250 pcs/min (for chemical bags) |

| Tube Width Range | 350-680mm |

| Tube Length Range | 500-1350mm |

| Layer Configuration | 2-4 layers of paper + 1 layer of PE film, paper |

| Tube Types | Staggered cutting, straight cutting with tearing separation |

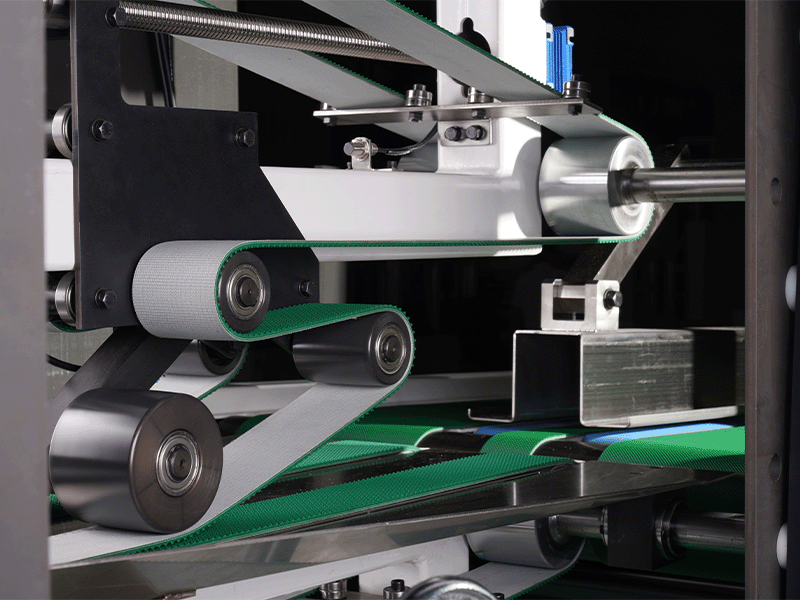

| Unwinding Specifications | Max diameter 1300mm, max width 1400mm |

| ntermittent Perforation | 5-25mm (4 stitch distances optional for single paper), switchable single/double cams |

| Transverse Creasing | Servo automatic diameter adjustment, switchable single/double cutters |

| Transverse Gluing | Switchable single/double row gluing modes |

| Middle Seam Gluing | Switchable single/double gluing discs |

| Total Power | 85kW |

| Dimensions | L40m×W2.98m×H3.2m |

| Weight | Approximately 40t |

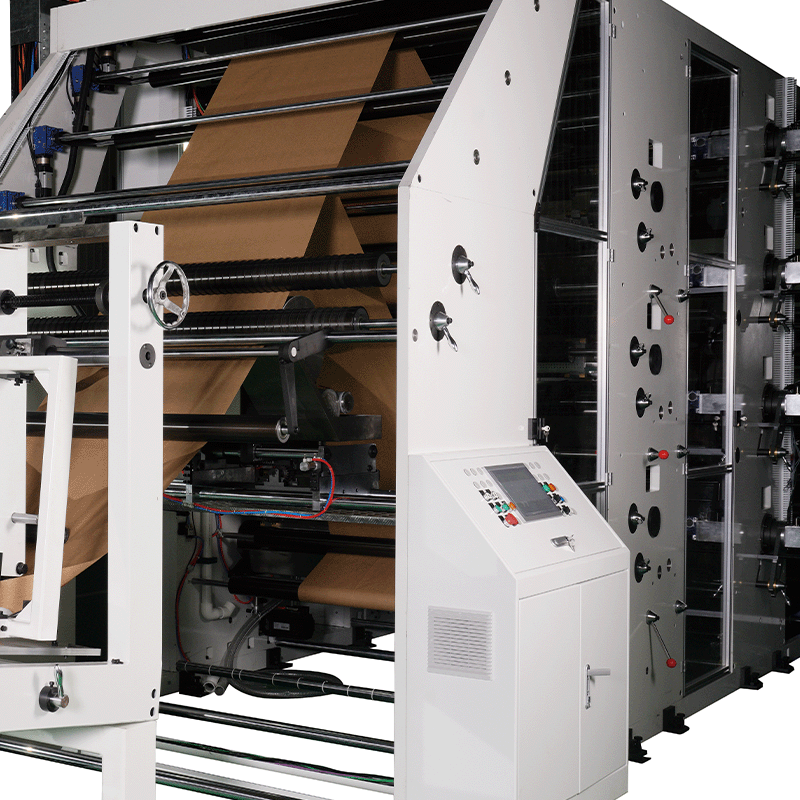

Unwinding Stand → Web Guiding → Intermittent Perforation → Transverse Creasing → Transverse Gluing → Middle Seam Gluing → Tube Forming → Traction Tearing (Creasing) → Conveying, Sorting & Separation → Stacking & Discharging

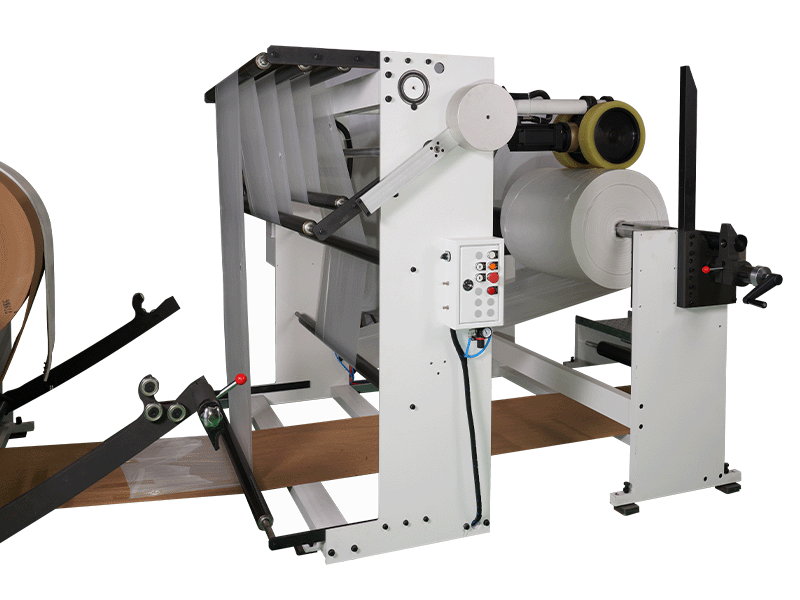

1.1 Equipped with 4 paper roll stands (with auxiliary paper support frames), 1 active film unwinding stand (with servo-driven active unwinding), 1 set of paper layering frames, 5 paper roll air shafts, 5 sets of brake linings, and 1 control switch per stand.

1.2 Max roll diameter 1300mm, max width 1400mm for each roll. The face paper roll stand is equipped with an electronic web guiding control system.

2.1 Composed of 4 sets of front paper passing rollers, 4 sets of rear friction rubber rollers, 4 sets of electronic guiding instruments and probes.

2.2 Functions: Guides paper feeding and positions for longitudinal gluing and forming. Guiding probes can be adjusted horizontally for different processes.

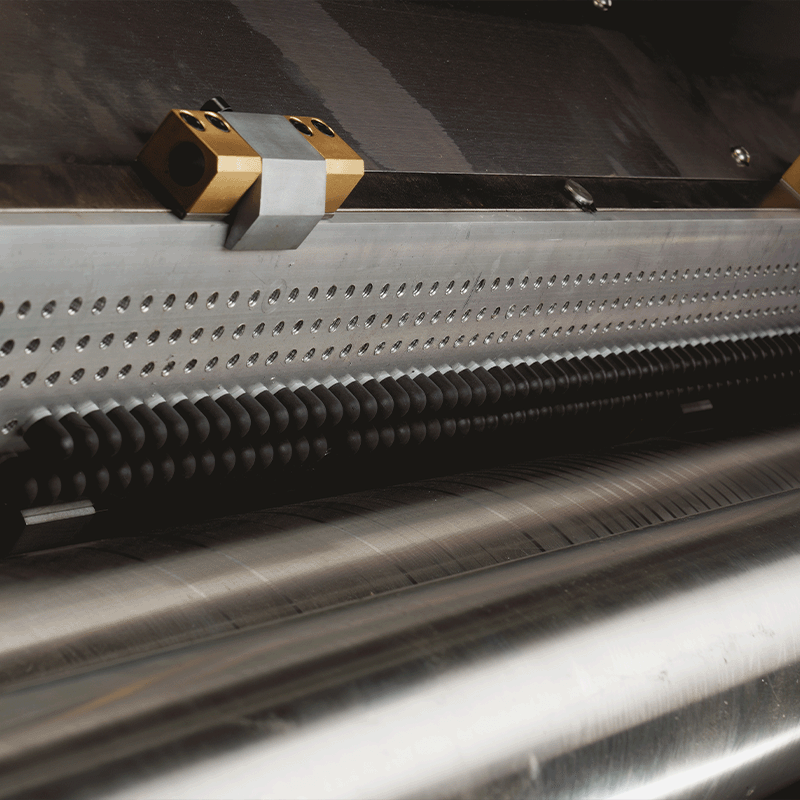

3.1 Equipped with 4 sets of intermittent perforation mechanisms, each consisting of 1 set of brush bottom rollers, 4 sets of perforation needle sleeves per paper layer (switchable online for different processes), 1 set of auxiliary traction (servo + timing belt drive), and 1 set of lifting cams (servo + timing belt drive, switchable single/double cams).

3.2 Driven by 1 set of servo synchronous control and 1 set of servo-controlled double-cam synchronous drive, with 1 set of color sensor control; Drive method: Servo + timing belt.

3.3 Perforation length adjustable via data settings to meet bag ventilation requirements.

3.4 Equipped with 1 set of control switches.

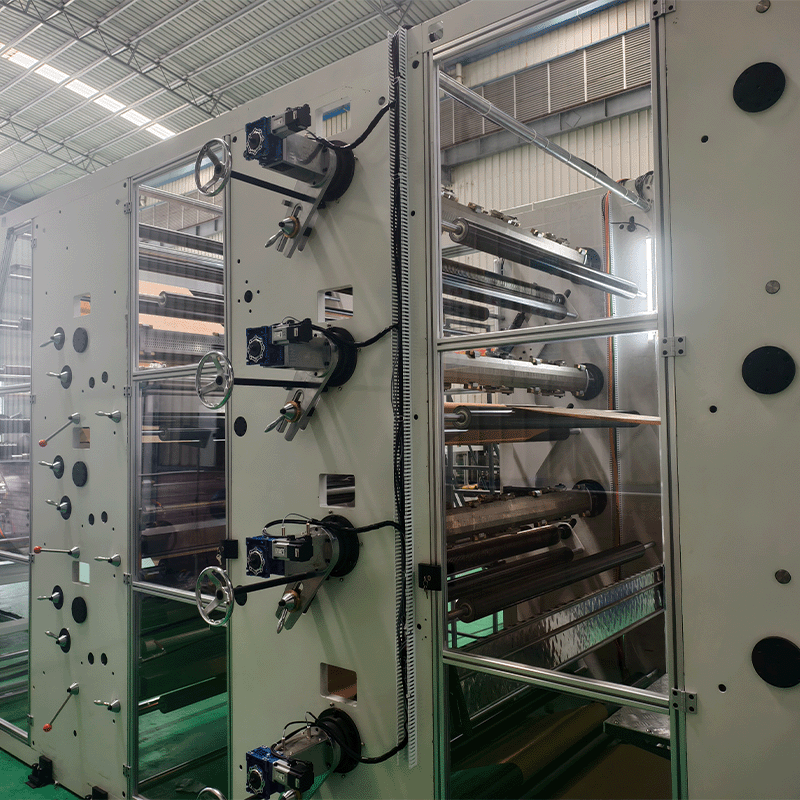

4.1 Equipped with 4 sets of automatic diameter-adjusting creasing mechanisms, each containing 1 M-cutter (servo-controlled automatic diameter adjustment for synchronous high-speed operation) and 1 anvil roller set (fixed connection for coordinated movement, servo-controlled position adjustment, and left-right adjustment for curved knife processes).

4.2 Driven by 1 set of servo synchronous control with color sensor control; Drive method: Servo + timing belt. Switchable single/double creasing knives.

4.3 Equipped with 1 set of control switches.

5.1 3 sets of transverse gluing mechanisms, each consisting of 1 gluing roller (large diameter, synchronized with gluing roller), 1 glue homogenizing roller (small diameter, slower speed), and 1 glue pan. Gluing rollers feature switchable single/double row gluing.

5.2 Front-rear position and layer differences adjustable via servo control for different processes.

5.3 Driven by 1 set of servo synchronous control with color sensor control; Drive method: Servo + timing belt. Switchable single/double gluing.

5.4 Equipped with 1 set of control switches.

6.1 Composed of 1 gluing roller (synchronized with middle seam gluing disc), 1 glue homogenizing roller, 1 glue pan, switchable single/double gluing discs for 2-4 layers, and 4 sets of layered staggering adjustments (servo-controlled).

6.2 Shared color sensor control with transverse gluing; Drive method: Servo + timing belt. Switchable single/double gluing.

6.3 Integrated with 1 main electrical cabinet (servo drives), 1 main operation panel (HMI, switches, indicators), and 1 speed display.

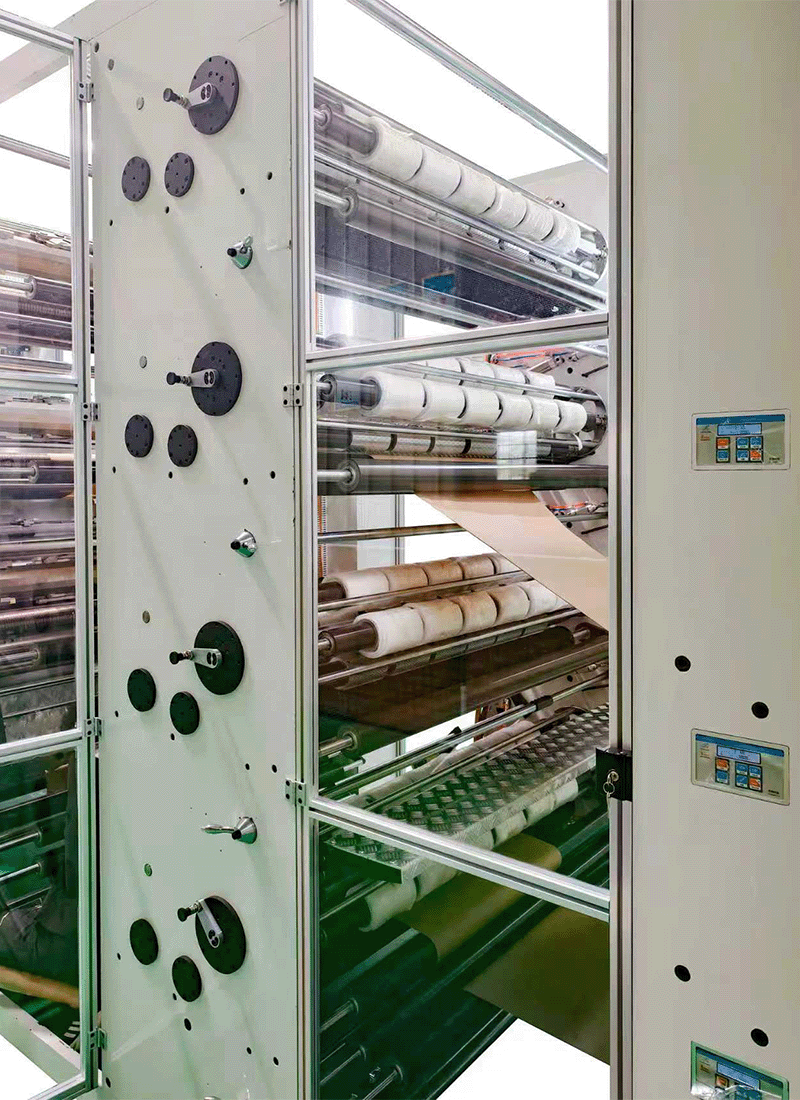

7.1 Forming frame with synchronized left-right adjustment, folding via pressure rollers and paper guides, and lift-up bottom plate for optimal forming.

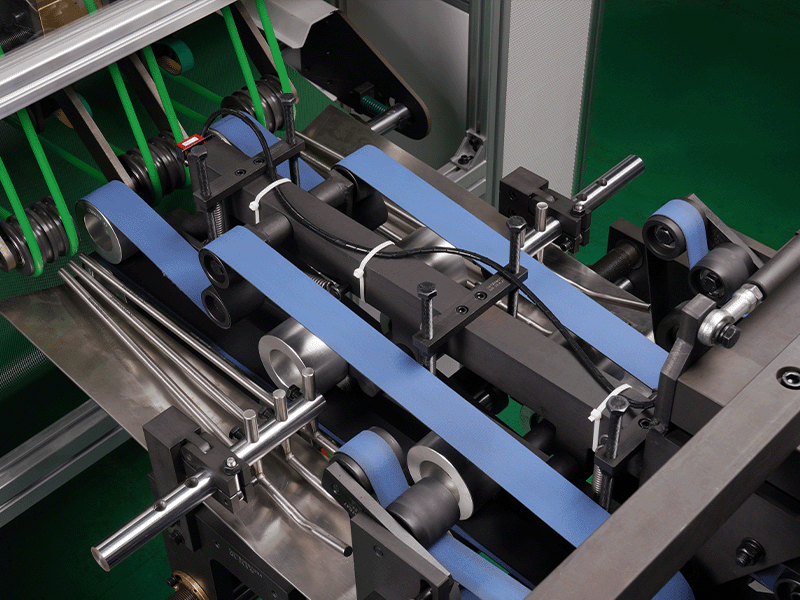

8.1 Equipped with 1 M-cutter (servo-controlled automatic diameter adjustment), 1 anvil roller set, front traction conveyor (upper-lower belt pinch), rear acceleration tearing conveyor (upper-lower belt lift-up pinch), tearing acceleration output belt rollers, and tearing cam drive assembly (switchable single/double cams).

8.2 Front traction: Servo synchronous control; Tearing lift cam: Servo synchronous control; Creasing/tearing: Color sensor synchronization; Drive method: Servo + timing belt.

8.3 Equipped with 1 set of control switches.

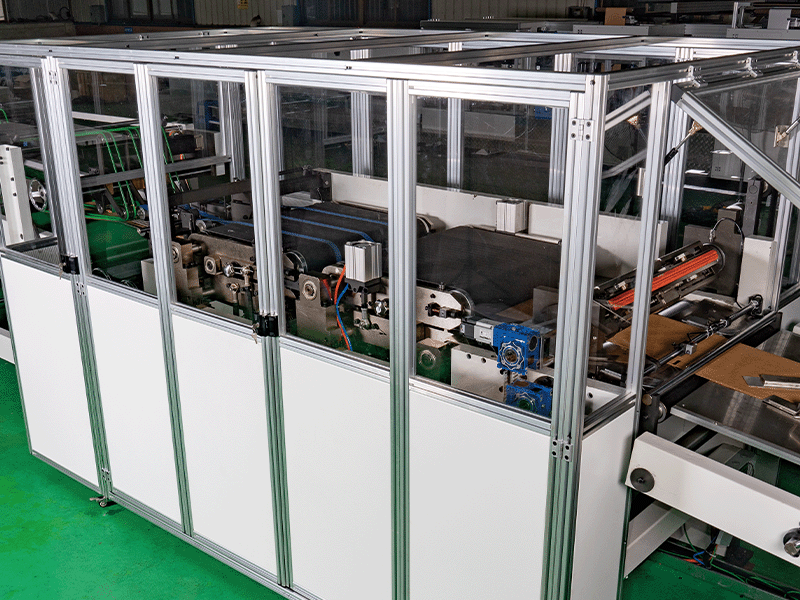

9.1 Composed of front receiving conveyor, transition sorting conveyor, and separation conveyor (high-frequency motor + timing belt drive).

9.2 Inclined conveying with anomaly detection sensors. Separation length adjustable by tube size.

9.3 Equipped with 1 set of control switches.

10.1 Includes stacking platform, discharge conveyor belt, and bag collection platform.

10.2 Equipped with 1 set of control switches.

Buyer provides sample bags; Seller provides 3 rolls of paper and auxiliary materials. Equipment configuration, unit operation, production speed, smoothness, and bag quality will be verified and confirmed via signed on-site agreement.

(1)Mechanical/electrical specifications comply with contract requirements.

(2) Routine inspection of components (rust, damage, appearance).

(3)Rotating parts, handles, guide rollers operate smoothly; Electrical/pneumatic components function stably; Instruments display accurately.

(4)After commissioning: 8-hour continuous production test at ≥150 pcs/min with no abnormal noise/heating, meeting quality and pass rate requirements.

|

Environmental Requirements |

|

| Power Supply | Three-phase 380V±10%, 50Hz |

| Compressed Air | Pressure 0.6 MPa Flow ~0.5m³/min Oil/water content ≤8mg/m³ |

| Installation Altitude | Max. 1500m |

| Ambient Conditions | Relative humidity :≤65% at 40℃ Indoor temperature :10-40℃ |

| Workshop Requirements | |

| Workshop Requirements | Height: ≥6m (for bottom pasting machine) Height: ≥5m (for tube making machine) Floor Levelness: ≤10mm error within equipment placement area Good drainage ton crane required at unwinding section |

| TBGS2025 High-Speed Intelligent Tube Making Machine Key Component Brand List | |||||

| No. | Component | Manufacturer | No. | Component | Manufacturer |

| 1 | HMI (Touch Screen) | B&R (Austria) | 17 | Ultrasonic Sensor | Insa |

| 2 | PLC Controller | B&R (Austria) | 18 | Arrow Button | Schneider |

| 3 | Main Motor | Guangdong Jiangsheng | 19 | Green Button | Schneider |

| 4 | Color Sensor | Keyence (Japan) | 20 | Red Indicator Light | Schneider |

| 5 | Vacuum Pump | Busch (Germany) | 21 | Positioning Servo Motor | Kesi |

| 6 | Web Guiding System | Dongguan Dongdeng | 22 | Inverter | Inovance |

| 7 | Gear Reducer | Baster | 23 | Transformer | Tianzheng |

| 8 | Steering Gearbox | Baster | 24 | Encoder | Omron |

| 9 | Traction Servo Motor | Peiye | 25 | M12 Proximity Switch | Biduk |

| 10 | Round Diffuse Sensor | Biduk | 26 | M8 Proximity Switch | Biduk |

| 11 | Gateway | Yutaike | 27 | 2-Position Rotary Switch | Schneider |

| 12 | Emergency Stop Switch | Schneider | 28 | Green Button | Schneider |

| 13 | Mirror Reflection Sensor | Leuze | 29 | Angle Sensor | Xiyu |

| 14 | Bearings | NSK (Japan) | 30 | Sub-HMI | Kunlun |

| 15 | Solenoid Valve | SMC (Japan) | 31 | Pneumatic Brake | Shanghai Handong |

| 16 | Low-Voltage Electrical Parts | Schneider or equivalent | |||

Driving the Industry to New Heights.Efficiency Redefined, Innovation Unleashed.