In the competitive industrial packaging world, efficiency and reliability are key factors determining a manufacturer's success. Valve bag packaging machines play a crucial role in ensuring that bulk materials—such as cement, chemicals, or building materials—are packed securely and efficiently. However, choosing between a manual and an automatic valve bag packaging machine can be a challenging decision for businesses looking to optimize productivity.

This article explores the major differences between the two types, their pros and cons, and how manufacturers can make the right investment decision to match their production goals.

Understanding Manual Valve Bag Packaging Machines

Manual valve bag packaging machines require operator involvement during the filling, sealing, and stacking processes. They are typically used by small or medium-sized production facilities or businesses with flexible packaging requirements.

Key characteristics of manual machines include:

- Operator-assisted bag feeding and sealing

- Basic mechanical or pneumatic control systems

- Lower initial investment

- Suitable for multiple bag types and short production runs

Manual valve bag machines are valued for their simplicity and versatility. Operators can easily switch between bag sizes and materials without complex adjustments. This flexibility makes them ideal for manufacturers with diverse packaging needs or those in the early stages of automation.

However, the limitation of manual systems lies in their dependence on human labor. Productivity, consistency, and quality can fluctuate based on operator skill and experience. For growing businesses, this often becomes a bottleneck as production scales.

Exploring Automatic Valve Bag Packaging Machines

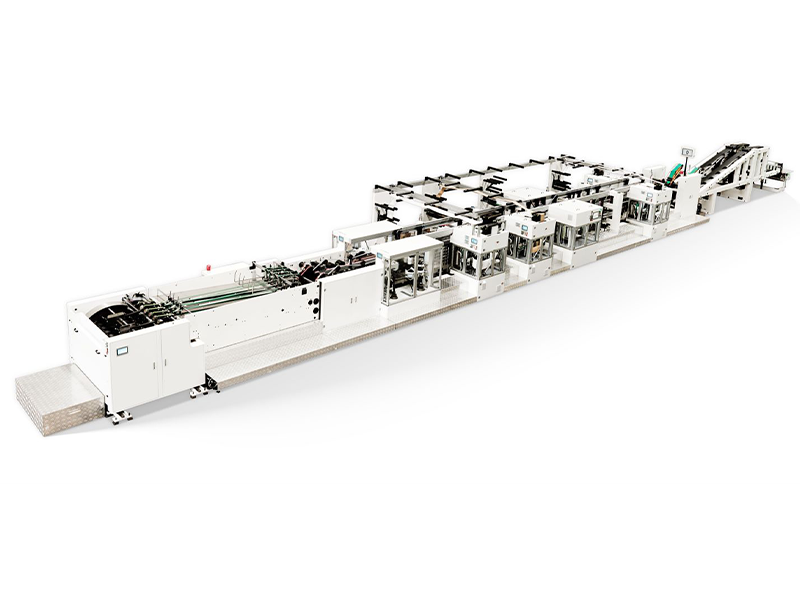

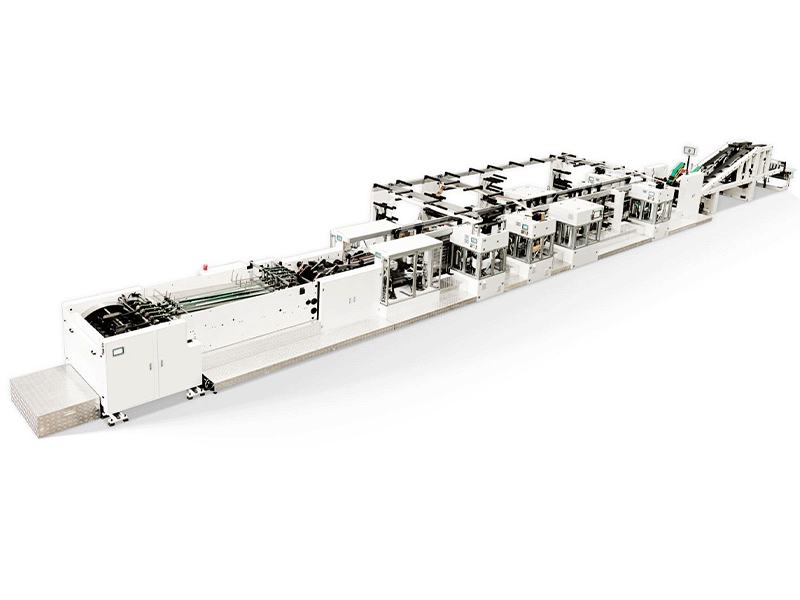

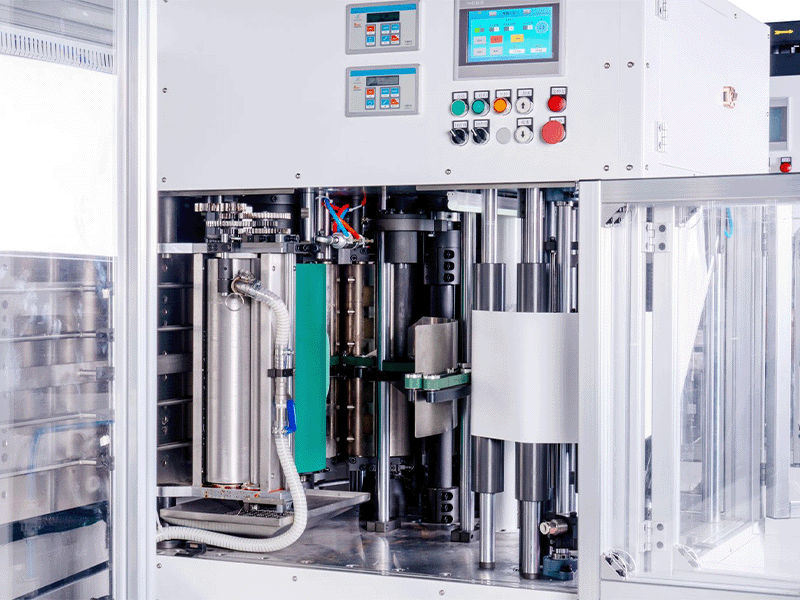

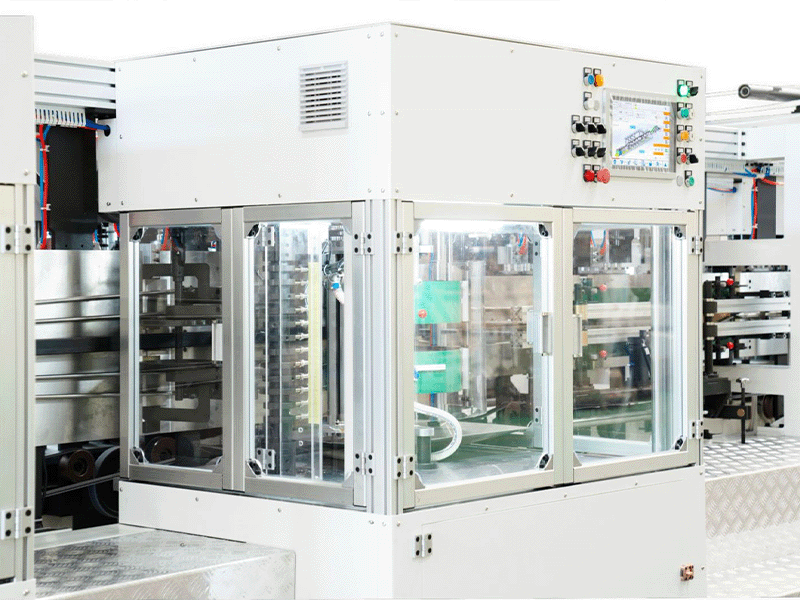

Automatic valve bag packaging machines, on the other hand, are designed to minimize manual intervention. With advanced control systems, servo motors, and automated bag handling, these machines deliver consistent performance, faster output, and higher precision.

Key advantages include:

- Automatic feeding, filling, and sealing operations

- Consistent bag quality and weight accuracy

- Reduced labor requirements and improved safety

- Higher operational efficiency and reduced downtime

Automatic systems are engineered for high-volume, continuous production environments, where precision and output are critical. They ensure uniform bag quality and sealing strength, which directly improves product integrity during storage and transport.

Leading manufacturers such as DESHENG have focused on enhancing automation by integrating smart control systems and precision gluing technologies into their valve bag machines. DESHENG's automatic solutions are designed to help factories achieve greater productivity while maintaining consistent quality, making them a strong choice for industries seeking efficient and reliable production lines.

Comparing Productivity: Manual vs Automatic Systems

When comparing productivity, automatic valve bag packaging machines clearly outperform manual models. Their automated bag feeding and gluing systems reduce idle time and operator dependency. This not only boosts production speed but also improves overall process stability.

Manual systems, while cost-effective initially, often struggle to maintain output consistency as demand increases. They require more workforce coordination and result in higher operating costs in the long term. In contrast, automatic machines streamline the workflow, allowing operators to focus on quality monitoring rather than repetitive manual tasks.

Operational Flexibility and Maintenance

One common misconception is that automatic machines are difficult to maintain. In reality, well-designed systems, such as those by DESHENG, prioritize modular structures and accessible components, making maintenance straightforward. Regular cleaning and routine checks are often sufficient to ensure long-term stability.

Manual systems, on the other hand, are simpler in structure but require constant human supervision. They can be prone to inconsistency if not properly managed. For companies operating in environments where labor reliability is a concern, automation provides a more sustainable long-term solution.

Cost Considerations and Return on Investment

While manual valve bag machines come with a lower upfront cost, automatic systems typically provide a faster return on investment due to reduced labor costs and higher throughput. The long-term savings in manpower, material waste, and downtime often outweigh the initial investment difference.

For businesses with steady or growing demand, transitioning to automation can significantly improve overall operational efficiency. DESHENG's automatic valve bag packaging machines are designed to balance cost and performance, offering flexible configurations that fit both medium-scale and large-scale manufacturing environments.

Making the Right Choice for Your Production Line

Ultimately, the choice between manual and automatic valve bag packaging machines depends on your production volume, budget, and growth strategy.

- If your business handles small batches or multiple bag variations, a manual machine offers flexibility at a lower cost.

- If your priority is scalability, efficiency, and consistency, an automatic machine provides better long-term value.

Manufacturers such as DESHENG offer both standard and enhanced valve bag packaging solutions to meet varying customer requirements. Whether upgrading from a manual system or setting up a new automated production line, DESHENG's engineering expertise and quality assurance ensure that every investment supports higher productivity and operational reliability.

Conclusion

The transition from manual to automatic valve bag packaging machines represents more than a technological upgrade—it reflects a commitment to efficiency and growth. While manual systems remain suitable for smaller operations, automation enables manufacturers to maintain competitiveness in demanding markets.

By partnering with reliable suppliers like DESHENG, businesses can achieve the right balance of technology, performance, and cost-effectiveness in their packaging operations.