In modern cement manufacturing, packaging is no longer a simple end-of-line task. It is a critical part of production efficiency, cost control, and product quality. As cement producers face increasing pressure to improve throughput, reduce dust emissions, and maintain consistent bag weights, the valve paper bag packaging machine for cement packing lines has become an essential solution.

At DESHENG, we have worked closely with cement plants around the world and understand the real challenges behind cement bagging operations. In this article, we explain how valve paper bag packaging machines work, why they are ideal for cement packing lines, and how the right equipment can significantly improve productivity and reliability.

Understanding Cement Packing Line Requirements

Cement is a fine, abrasive powder with high fluidity and strong dust generation characteristics. These properties create several challenges during packaging:

- Maintaining accurate bag weight at high speeds

- Preventing dust leakage during filling

- Ensuring stable bag sealing for transportation and storage

- Achieving continuous, automated operation in large-scale cement plants

Traditional open-mouth bagging systems often struggle to meet these demands efficiently. This is where valve paper bag packaging machines become the preferred solution for cement manufacturers.

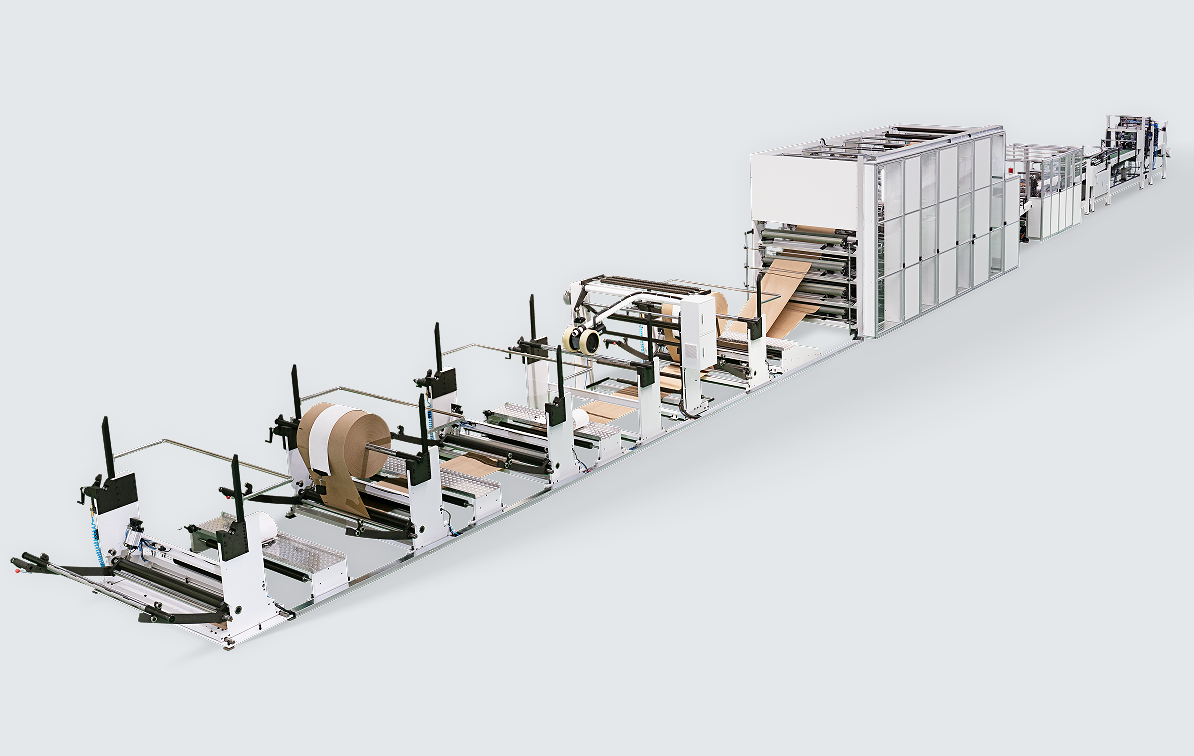

What Is a Valve Paper Bag Packaging Machine?

A valve paper bag packaging machine is designed to fill cement into pre-made valve bags through a self-closing valve opening. Unlike open-mouth bags, valve bags seal automatically once filling is complete, using internal air pressure and product weight.

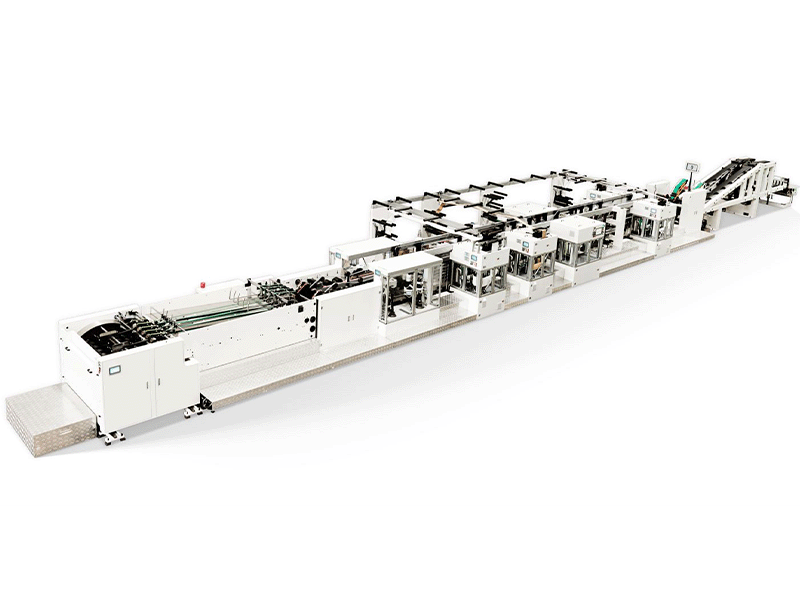

In cement packing lines, these machines are typically integrated with:

- Cement silos and discharge systems

- Weighing and dosing units

- Bag placers or manual bag feeding stations

- Conveyors, bag flatteners, and palletizing systems

At DESHENG, we design valve paper bag packaging machines specifically for cement, building materials, and mineral powder applications, ensuring compatibility with demanding industrial environments.

How Valve Paper Bag Packaging Machines Work in Cement Packing Lines

A typical cement packing process using a valve paper bag packaging machine includes the following steps:

- Bag placement – The empty valve paper bag is positioned on the filling spout

- Automatic filling – Cement flows into the bag under controlled pressure

- Weight control – Mechanical or electronic weighing systems ensure precise filling

- Self-sealing – Once filling stops, the valve closes automatically

- Bag discharge – The filled bag moves to downstream conveying equipment

This process allows continuous, high-speed cement packing with minimal manual intervention.

Why Valve Paper Bag Packaging Machines Are Ideal for Cement

1. High-Speed Cement Packing Performance

Cement plants operate under high-volume conditions. A well-designed valve paper bag packaging machine can handle hundreds to thousands of bags per hour, making it ideal for large-scale cement packing lines.

Our systems at DESHENG are engineered to maintain consistent speed even during long production shifts, helping cement producers meet output targets without sacrificing quality.

2. Accurate Weight Control for Cement Bags

Weight accuracy is a critical requirement in cement packaging. Overfilling leads to material waste, while underfilling causes compliance issues and customer complaints.

Valve paper bag packaging machines use precise dosing mechanisms to ensure each cement bag meets weight specifications. We offer different weighing solutions depending on production needs, allowing cement manufacturers to balance speed and accuracy effectively.

3. Dust-Free and Cleaner Cement Packaging

Dust control is one of the biggest challenges in cement packing lines. Excessive dust not only affects the working environment but also leads to material loss and equipment wear.

Valve paper bag packaging machines significantly reduce dust emissions because:

- The filling spout is sealed by the valve bag

- Cement flow is controlled and enclosed

- The valve closes immediately after filling

At DESHENG, we further enhance dust control through optimized spout design and optional dust extraction interfaces.

4. Strong Bag Sealing for Transport and Storage

Valve paper bags are widely used in cement packaging because of their excellent sealing performance. Once filled, the valve closes automatically without additional sealing steps.

This ensures:

- Reduced risk of leakage during transportation

- Better stacking stability

- Improved product appearance

For cement producers exporting or distributing over long distances, this sealing reliability is a major advantage.

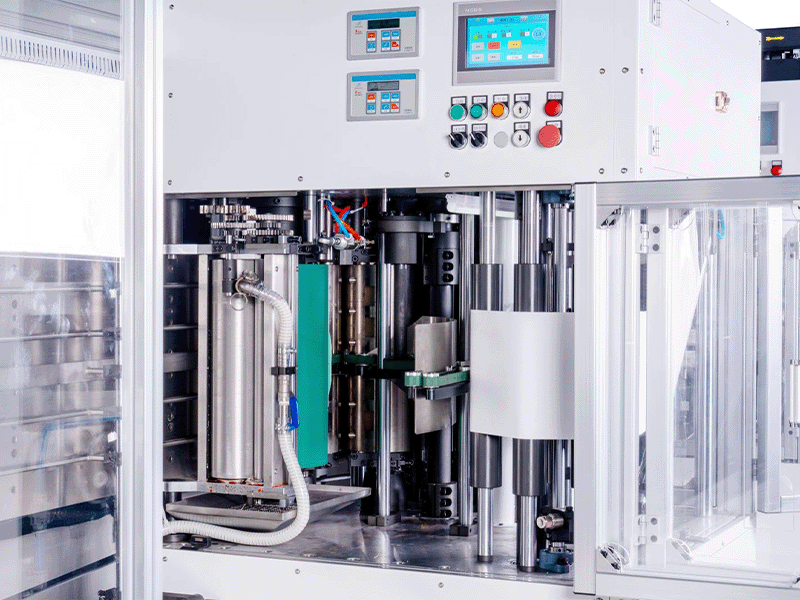

Key Components of a Cement Valve Bag Packaging Machine

A high-performance valve paper bag packaging machine for cement packing lines typically includes:

- Filling spouts designed for abrasive cement powder

- Dosing and weighing system for precise bag weight

- Bag clamping mechanism to ensure stable filling

- Control system for speed and accuracy adjustment

- Heavy-duty frame suitable for industrial environments

At DESHENG, we focus on durability and long-term stability, selecting wear-resistant materials and proven mechanical structures to handle cement's abrasive nature.

Automatic vs Semi-Automatic Cement Packing Lines

Semi-Automatic Valve Paper Bag Packaging Machines

- Manual bag placement

- Suitable for small to medium cement plants

- Lower initial investment

- Flexible operation

Fully Automatic Valve Paper Bag Packaging Machines

- Automatic bag feeding and placement

- Higher output and labor savings

- Ideal for large-scale cement production

- Easier integration with palletizing systems

We help our customers choose the right level of automation based on production capacity, labor availability, and long-term expansion plans.

Integration with Complete Cement Packing Lines

A valve paper bag packaging machine is most effective when integrated into a complete cement packing line. This may include:

- Bag conveyors

- Checkweighers

- Bag flatteners

- Robotic or conventional palletizers

DESHENG provides not only standalone machines but also complete cement packaging solutions, ensuring smooth system integration and stable operation from silo discharge to palletized cement bags.

Maintenance and Reliability in Cement Applications

Cement is highly abrasive, making machine reliability a key concern. Poorly designed equipment can suffer from rapid wear, frequent downtime, and inconsistent performance.

Our valve paper bag packaging machines are designed with:

- Reinforced wear parts

- Easy-access maintenance points

- Stable mechanical structures

This helps reduce downtime and maintenance costs over the life of the cement packing line.

Why Choose DESHENG for Cement Valve Bag Packaging?

We understand that cement manufacturers are not just buying a machine — they are investing in long-term production efficiency.

When working with DESHENG, our customers benefit from:

- Proven experience in cement and building material packaging

- Customized solutions for different cement packing capacities

- Reliable machine performance under continuous operation

- Technical support and system integration expertise

Our goal is to help cement producers build packaging lines that are efficient, clean, and future-ready.

Conclusion

A valve paper bag packaging machine for cement packing lines is a critical investment for modern cement manufacturers seeking higher efficiency, better accuracy, and cleaner production environments. By choosing the right equipment and system design, cement plants can significantly improve packaging performance while reducing operational costs.

At DESHENG, we continue to focus on practical, reliable packaging solutions tailored to real cement production needs. Whether upgrading an existing packing line or building a new one, the right valve paper bag packaging machine makes a measurable difference in long-term success.