Valve mouth paper bag packaging machine is an automated equipment designed to accurately fill powdered or granular materials into valve pockets. This packaging machine can efficiently complete processes such as weighing, filling, and sealing of materials through advanced measuring systems and automation control technology. The characteristic of a valve pocket is that its opening has a valve or valve structure, which facilitates precise filling of materials without easy leakage.

The valve mouth paper bag packaging machine is widely used in industries such as chemical, building materials, food, and pharmaceuticals, and is suitable for packaging bulk materials such as cement, fertilizers, plastic pellets, flour, sugar, etc. These machines not only improve packaging efficiency, but also ensure packaging quality and the cleanliness of the production line.

In short, the valve mouth paper bag packaging machine plays an important role in multiple industries with its efficient and precise packaging capabilities, helping production enterprises improve production efficiency and product quality.

1.Solving Packaging Problems: Common Problems and Countermeasures of Valve Mouth Paper Bag Packaging Machine

Did you encounter the following issues during the packaging process:

-Does slow packaging speed affect production efficiency?

-Is the packaging not tight enough to cause material leakage?

-Is changing packaging specifications cumbersome and time-consuming?

-Frequent equipment failures and high maintenance costs?

Our valve mouth paper bag packaging machine provides the following solutions:

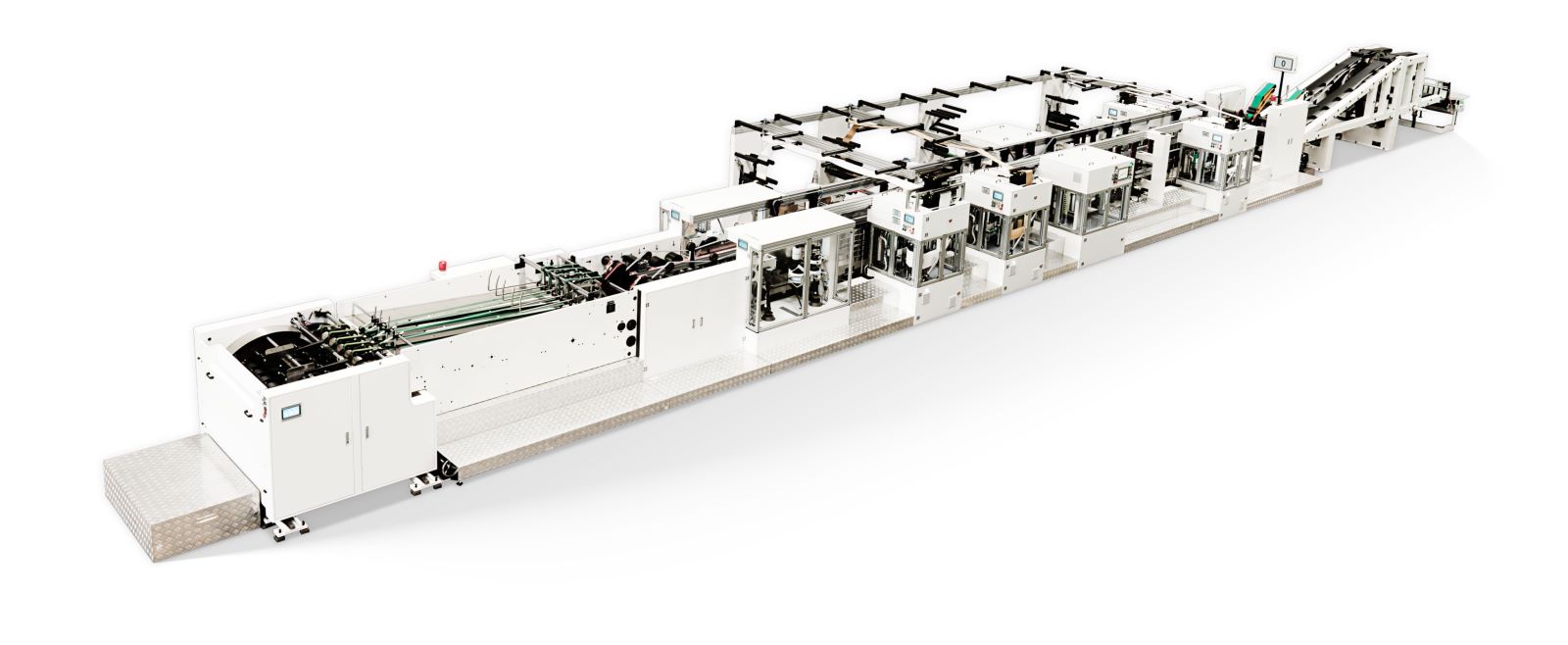

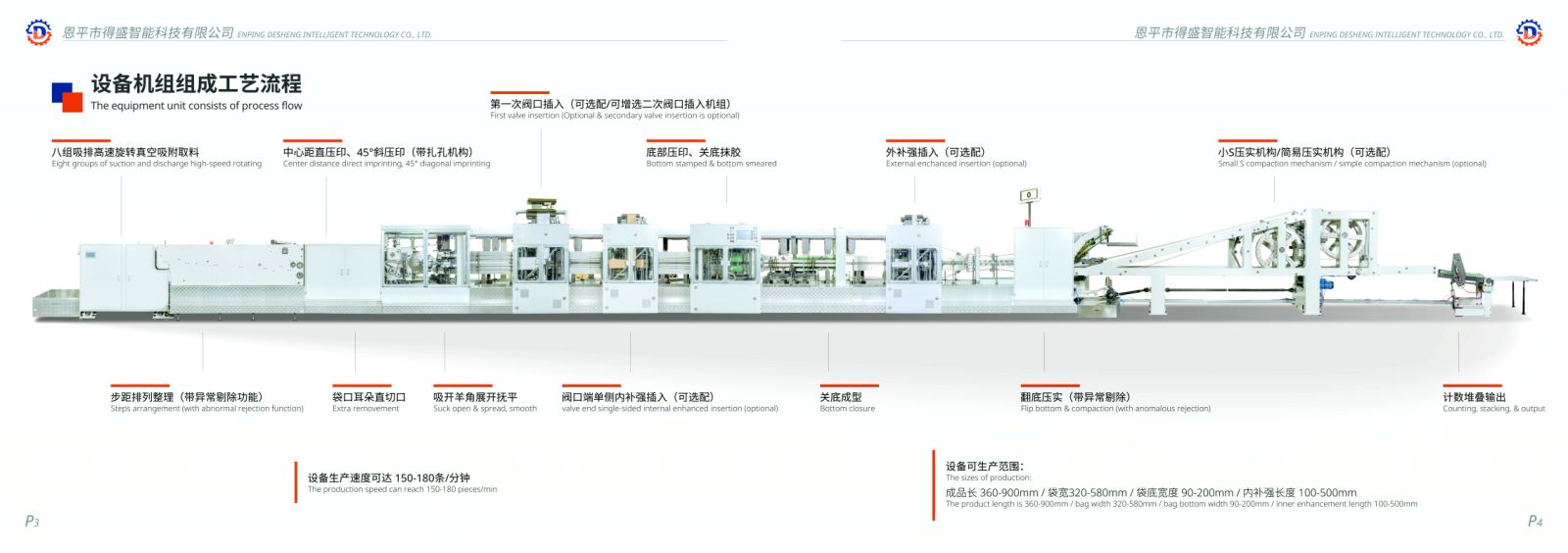

-Efficient packaging speed: The equipment production speed can reach 150-180 pieces/minute, greatly improving production efficiency.

-Good sealing: Advanced valve port design ensures tight packaging and prevents material leakage.

-Flexible adjustment: Supports multiple specifications of bags, quick switching, and adapts to different product needs.

-Intelligent control system: equipped with PLC control, easy to operate, reducing manual intervention.

-Durable and sturdy: Made of high-quality materials and precision manufacturing processes, the equipment has high stability and a long service life.

2.Avoiding Production Stagnation: Common Problems and Solutions for Valve Mouth Paper Bag Packaging Machines

①No input to PLC

Symptoms: The machine cannot start or respond to operating instructions.

Solution: Check whether the data cable plug is loose, consider replacing the controller or data cable.

②No signal from solenoid valve

Symptoms: The pneumatic components of the machine do not work.

Solution: Check whether the solenoid head is damaged, whether the PLC has an output signal, and whether the control line is broken.

③The cylinder suddenly does not move

Symptoms: The moving parts of the machine stop responding.

Solution: Check whether the solenoid valve is damaged, whether the cylinder seal is worn, and whether the PLC has an output signal.

④Out-of-tolerance phenomenon occurs during the packaging process

Symptoms: The packaging weight exceeds the allowable deviation.

Solution: Check whether the sensor connection is loose, whether it is disturbed by external forces, whether the silo is blocked, and whether the valve action is normal.

⑤Unstable packaging accuracy

Symptoms: The weight difference of continuous packaging is large.

Solution: Recalibrate the scale.

⑥Slow or no discharge

Symptoms: The material filling speed is too slow or stops completely.

Solution: Check whether there is blockage, adjust the feed rate, and check whether the air pressure is sufficient.

⑦ Instrument does not display

Symptoms: The display screen of the control panel does not respond.

Solution: Confirm that the power supply of the electric box is normal, check whether the three-phase power switch is normal, check whether the emergency stop switch is normal, check whether the instrument power supply 220V is normal, if normal, the instrument needs to be replaced.

⑧ Bag making is not neat

Symptoms: The shape of the packaging bag is irregular or uneven.

Solution: Check whether the feeding system is uniform and whether the sealing system is normal.

⑨ Material blockage

Symptoms: The material is blocked during the packaging process.

Solution: Check whether the material properties are suitable for packaging, adjust the material humidity or particle size, and clean the blocked parts.

⑩ Excessive noise

Symptoms: Abnormal noise is generated when the machine is running.

Solution: Check whether there are loose parts, poor lubrication or wear.

3.Our valve mouth paper bag packaging machine has the following advantages:

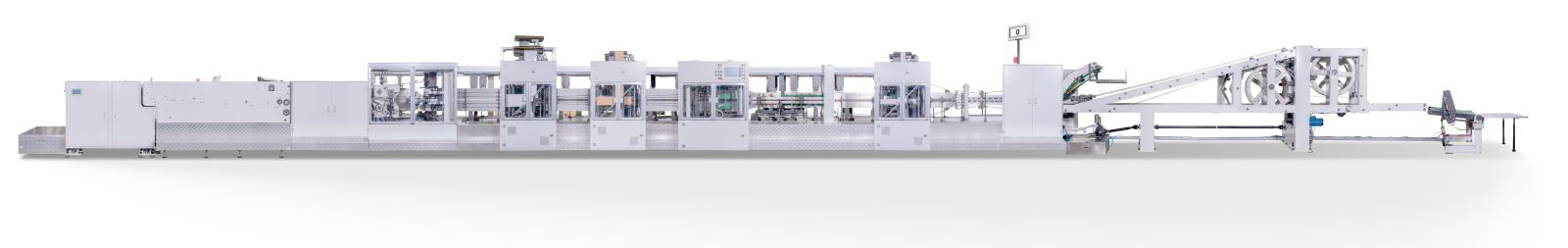

High degree of automation:

The highly automated operation process, from the feeding of raw materials to the output of finished bags, the entire production process can be completed automatically, reducing manual intervention and improving production efficiency.

Accurate measurement:

The equipment is equipped with a high-precision measurement system, which can accurately control the weight of packaging materials and meet the high requirements of chemical, food and other industries for product quality.

Environmentally friendly and clean production:

- The entire production process is controlled by PLC intelligent program to achieve continuous operation, and real-time monitoring, remote diagnosis and network management can be carried out through the communication interface.

- The new discharge port design of the device ensures the effective sealing of the inner and outer jackets, and the built-in air blowing device and the closing device in the discharge bag ensure that there is no residual material falling at the discharge port after the packaging bag exits the outlet, which solves the problem of large dust of ultrafine powder materials and realizes dust-free and clean production.

Stability and precision:

It has the characteristics of stable packaging performance and high precision for granular powder and ultrafine powder with large air content, ensuring that the packaging bag is full and beautiful, and the valve mouth does not drop material and is dust-free.

Wide applicability:

It is suitable for valve mouth packaging bags of various packaging materials such as kraft paper bags, coated woven bags, plastic bags, PE bags, aluminum foil bags, etc.

Comprehensive cost advantage:

- The packaging bags are easy to recycle and protect the ecological environment.

- With the application of new materials, the film thickness gradually decreases and the strength gradually increases. The comprehensive packaging cost of valve bags is better than that of traditional packaging forms.

Convenient maintenance:

- The body is fully sealed and equipped with dust removal ports. The structure is reasonable and durable, realizing environmentally friendly production.

- Small size, light weight, easy adjustment and maintenance.

Versatility:

It is not only used for dry mortar packaging, but also for the packaging of other powdery and granular materials with good flow properties.

Our valve mouth paper bag packaging machine is an ideal choice to improve packaging efficiency and ensure product quality. Contact us now to learn more about our products and get customized solutions. Let us drive your business together!

Contact: +86 13326818358